| | Custom embroidery emblem/ patch/ badge |

| | Polyester /Fabric /Cotton /Damask /Nylon /Camo

|

| | Part embroidery/ 100% embroidery/ Towel Chenille Embroidery/ Sequins embroidery |

| | According to customer demand

|

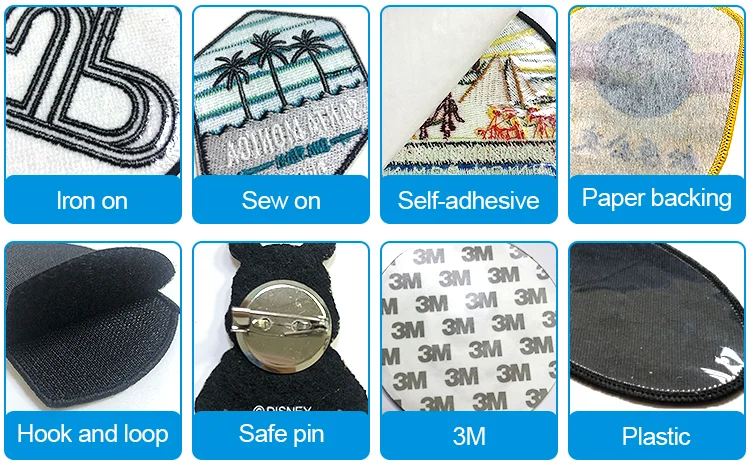

| | Iron on /Heat seal /Adhesive /Hook and loop /Plastic /Pin backing |

| | OPP/Bubble bag/Acrylic box/Paper box etc. |

| | Laser cut /Merrow border /Hot cut /Hand cut /Stitch border |

| | |

| | Sample: 3days,Mass production: 7~10days |

| | 30% advance payment to start production |

| | FedEx / DHL / UPS / TNT etc. |

Overview

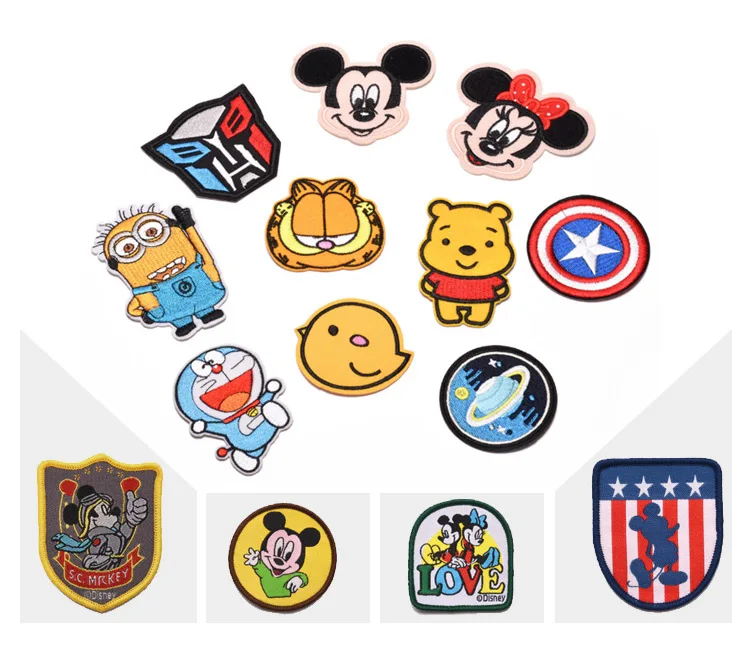

Custom Bear Patches represent the pinnacle of textile branding solutions, combining artisanal embroidery with commercial-grade resilience. Designed for fashion brands, corporate merchandisers, and sports teams, these patches transform ordinary garments into premium branded assets. Utilizing state-of-the-art computerized embroidery machines and UV-stable threads, each piece delivers photographic detail while withstanding harsh environmental conditions. The product line supports full customization across shapes, sizes (2–12 inches), and attachment methods, serving diverse applications from military insignias to children’s apparel. With OEKO-TEX® certification and ISO 9001-compliant production, these patches meet stringent international safety and quality benchmarks.

Features

1. 6-Stage Embroidery Process: Each patch undergoes digitizing, backing stabilization, underlay stitching, color-fill embroidery, border merrowing, and heat-sealing for dimensional stability.

2. Commercial Durability: Features a 0.8mm thick neoprene backing reinforced with industrial-grade adhesive (150°C melt point), achieving 35 N/cm² peel strength on ASTM D903 testing.

3. High-Fidelity Color Reproduction: Utilizes Madeira Aerolock® polyester threads with 600+ Pantone TPX color matches and 0.15mm stitch precision for complex gradients.

4. Multi-Application Backings: Select from sew-on woven twill, iron-on thermoplastic, or hook-and-loop (Velcro®-compatible) options with wash-cycle guarantees up to 80 cycles.

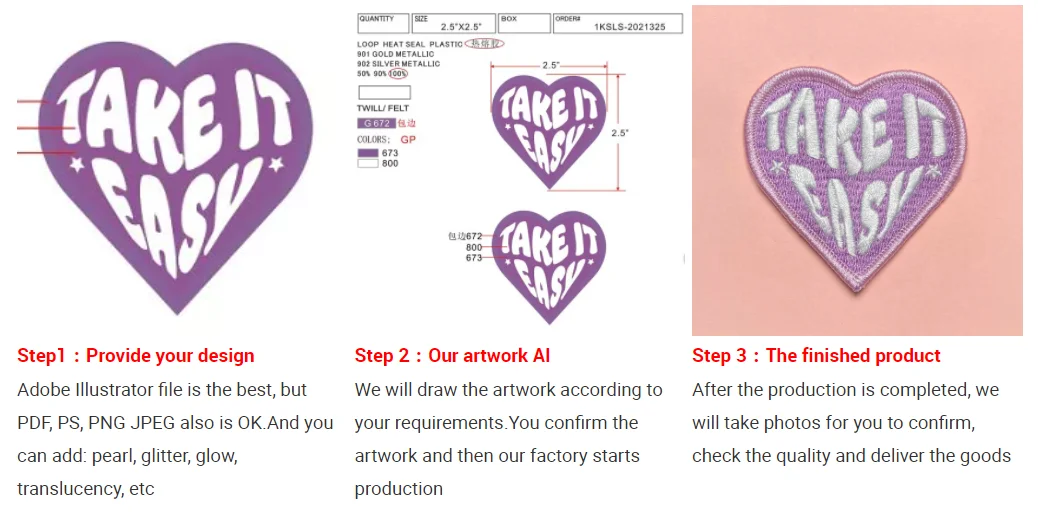

5. Rapid Prototyping Service: Submit artwork for a 3D digital mockup within 4 business hours, with physical samples shipped via DHL Express in 72 hours.

6. Sustainable Production: Option for GRS-certified recycled threads (30% post-consumer waste) and water-soluble PVC-free backings meeting EU Ecolabel criteria.

FAQ

Q: What’s the minimum embroidery detail size you can reproduce?

A: We maintain 0.3mm line clarity using 60wt micro-threads, capable of stitching text as small as 4pt font legibly.

Q: How do you ensure color accuracy across production batches?

A: Our computerized color-matching system auto-calibrates using SpectraScan® technology, maintaining ΔE ≤1.5 across all batches.

Q: Can patches be applied to leather or technical fabrics?

A: Yes, specify “heavy-duty” backing options during ordering for adhesion to leather, Gore-Tex®, or Kevlar® substrates.

Q: Do you offer weatherproofing treatments for outdoor use?

A: Optional Teflon® fabric protector coating available, achieving 80/80 ISO 4920 spray test ratings for water-repellent performance.

Q: How are patches packaged for international shipping?

A: Choose between polybagged units with anti-tarnish paper interleaving or custom-branded pegboard displays, shipped in moisture-proof corrugated boxes with desiccant packs.

How do I get a quote quickly?

PlS provide your design (AI,PS, CDR, PDF, JPG, PNG, etc.)

AND Tell me the following information:

Craft:Full embroidery or half embroidery

Size: ____ "(Height) x______"(length)

Quantity:_____ pcs

When do you need it by : _______.

Where to Shipping : ________(Country with postcode please)